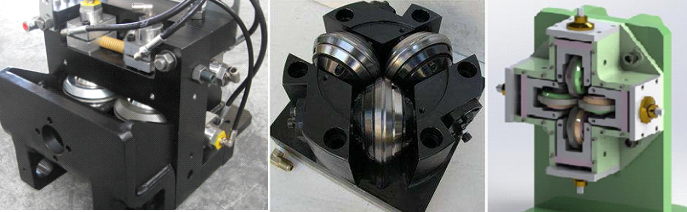

Roller drawing die is a new type of drawing die. Under the action of drawing force, the raw material (metal rod, metal wire, etc.) can pass through holes of specific shape and size to obtain the required shape and size of the shaped die. The holes in the roll drawing die are formed by grooves on the surface of each roll wheel combined together, and each roll wheel rotates continuously with the forward movement of the raw material.

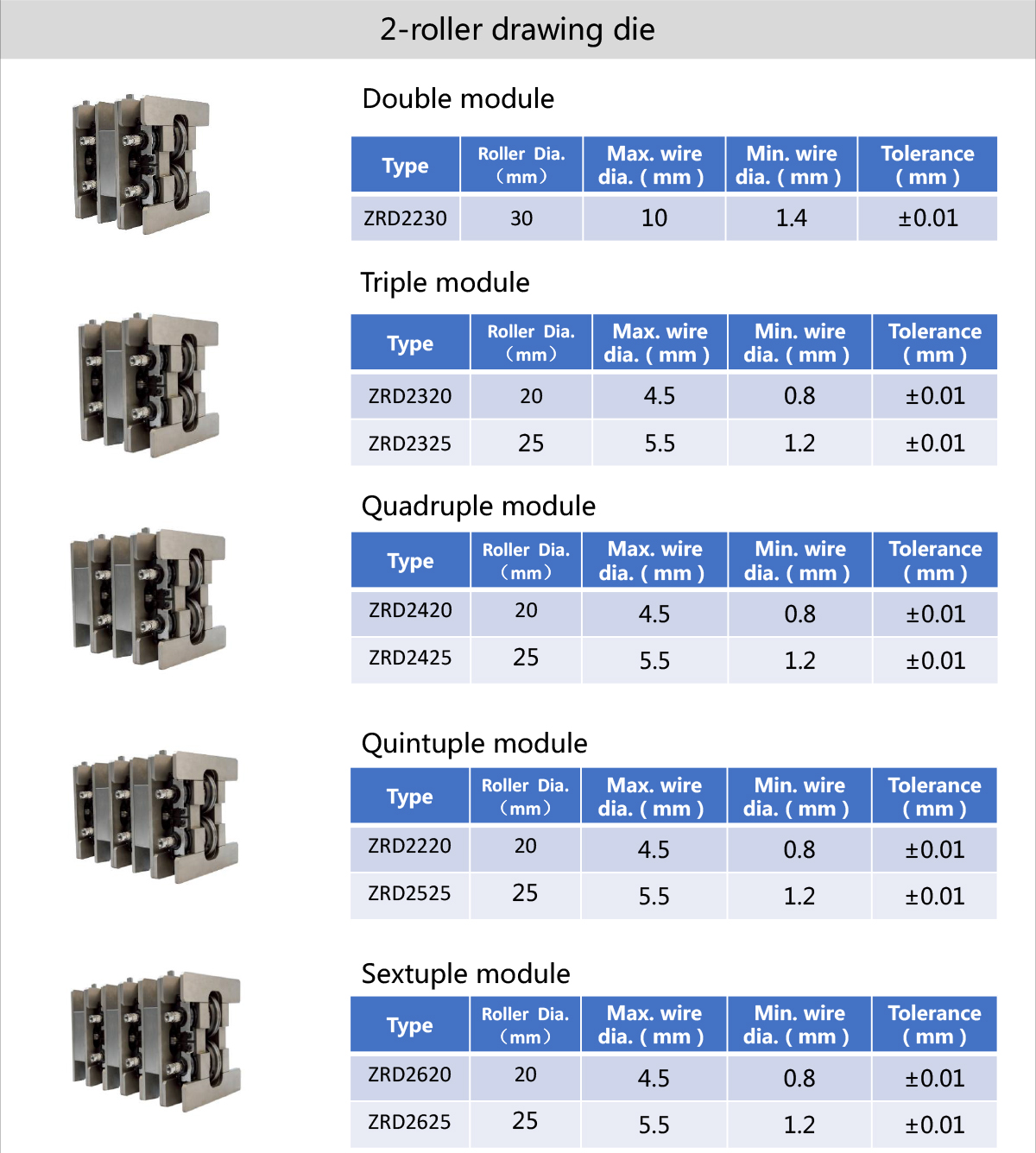

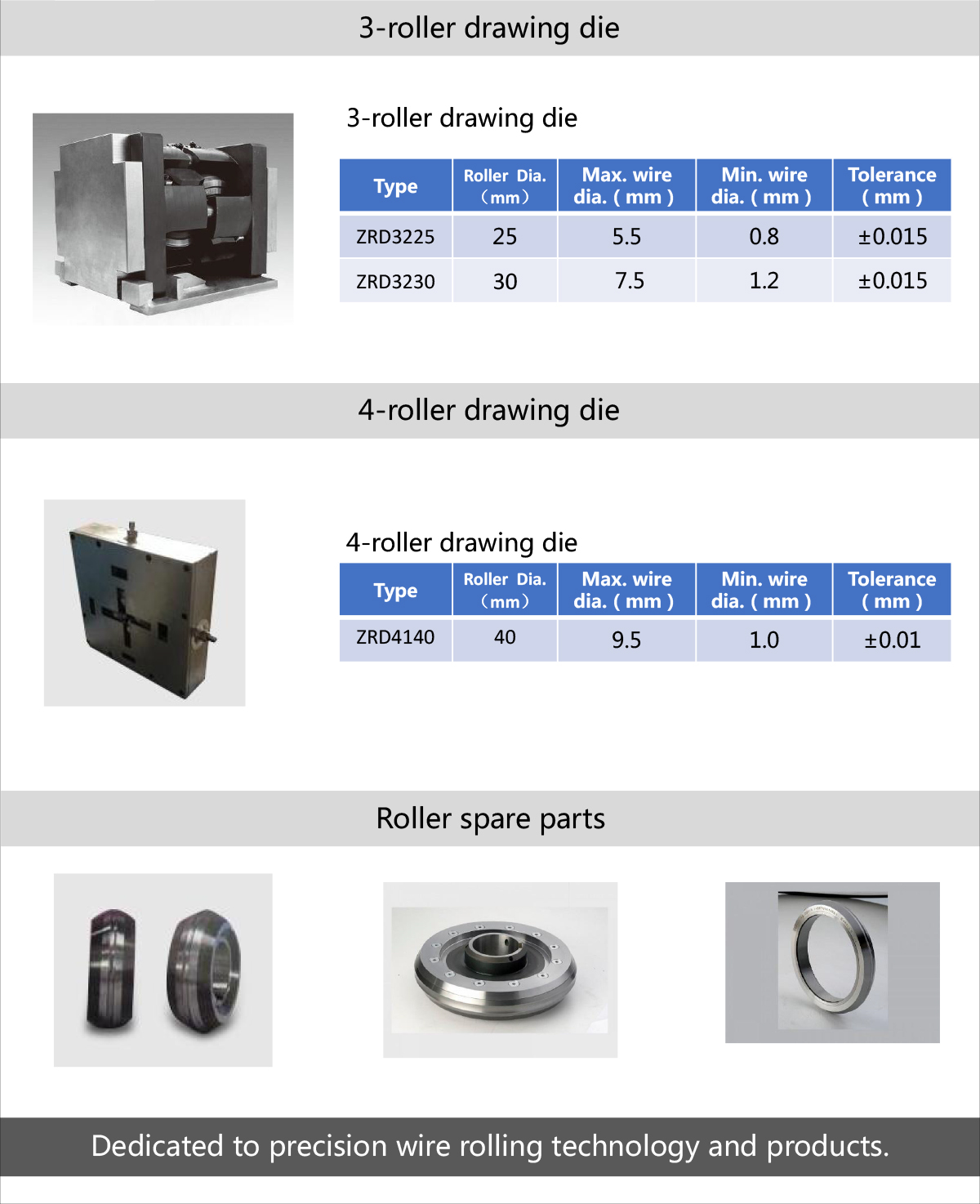

A roll drawing die consists of several modules. Each module is mainly composed of roll wheel and bracket. According to the number of modules in each roll drawing die, there are single, double, triple, quadruple, five, six. According to the number of rollers in a single module, there are two rollers, three rollers and four rollers. At present, in most occasions, roll drawing die has been able to replace the traditional drawing die, greatly improving the traditional drawing process. Compared with the traditional drawing die, roller drawing die reduces the drawing force, thus reducing the drawing power, thereby saving a lot of electricity.

In addition, the use of roll drawing dies also reduces the requirements for lubrication of dies, thus greatly reducing the use of wire drawing powder in the drawing process. Therefore, the pretreatment requirements of metal raw materials are greatly reduced (acid, phosphating solution, skin film agent, borax, etc., which are commonly used in the pretreatment process are reduced).

Product feature:

- Improve production efficiency. The production speed can be increased by 20%, the breaking rate can be reduced by 90%, and the changing time can be greatly reduced.

- The structure is novel, the volume is small, and the installation and adjustment are convenient.

- Good cooling and lubrication effect and long service life of roller.

- Increasing productivity or equipment utilization ratio: reducing shutdown time, reducing wire breakage rate, allowing wire drawing machine to speed up, improving equipment productivity.

- Improve the quality of outlet line: uniform radial structure of outlet line, improved mechanical properties, no lubricant powder surface, improved cleanliness;

- Energy saving, labor saving, part of the material can reduce the annealing pass, shorten the processing cycle;

- Improve the environment: reduce the use of drawing powder, clean workshop environment.

Application:

- Steel wire drawing, such as low carbon steel wire, high carbon steel wire (steel cord, cutting steel wire, pre-stressed steel wire, spring steel wire, etc.), stainless steel wire, welding wire, etc.

- Drawing of non-ferrous metals and their alloy wires, such as copper rods, copper alloys, titanium alloys, etc.

- Special-shaped metal wire drawing, such as cold-drawn ribbed steel bar, elliptical wire, hexagonal wire, triangular wire, etc.

- Tightening of wire rope.

- Drawing of steel pipe.

- Drawing of flux-cored wire.

- Drawing of composite metal materials, such as copper clad aluminium, aluminium clad steel, etc.