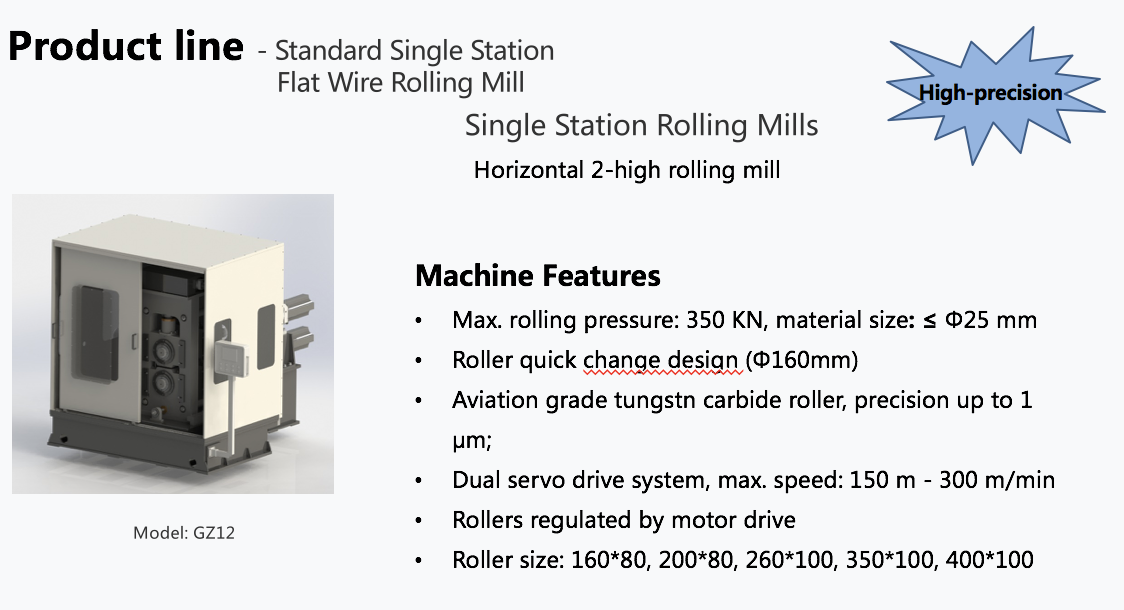

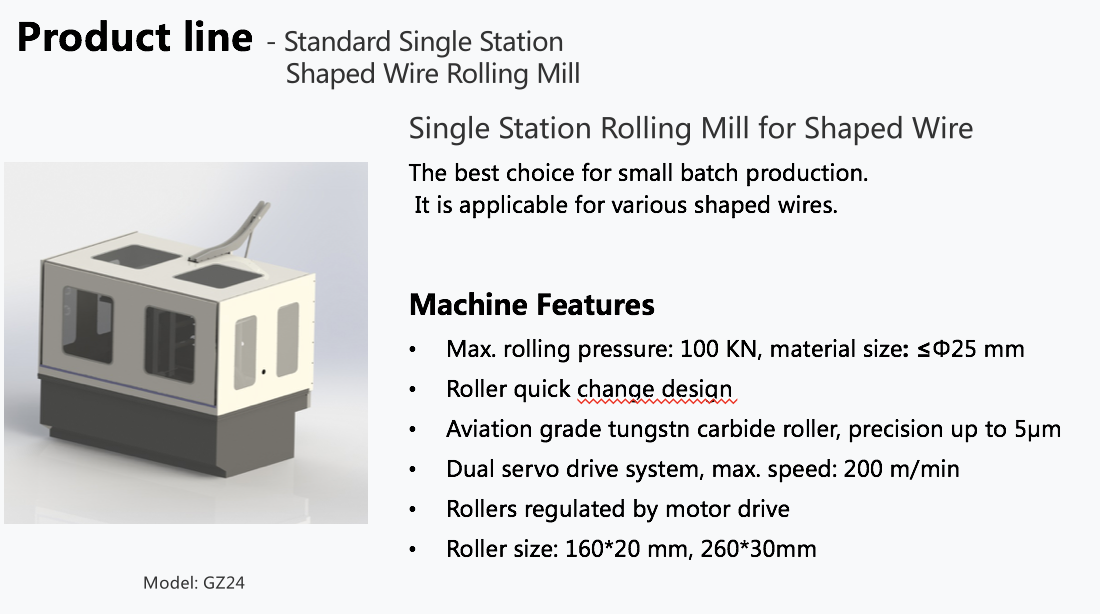

High Precision Metal Wire & Strip Rolling Mill Line

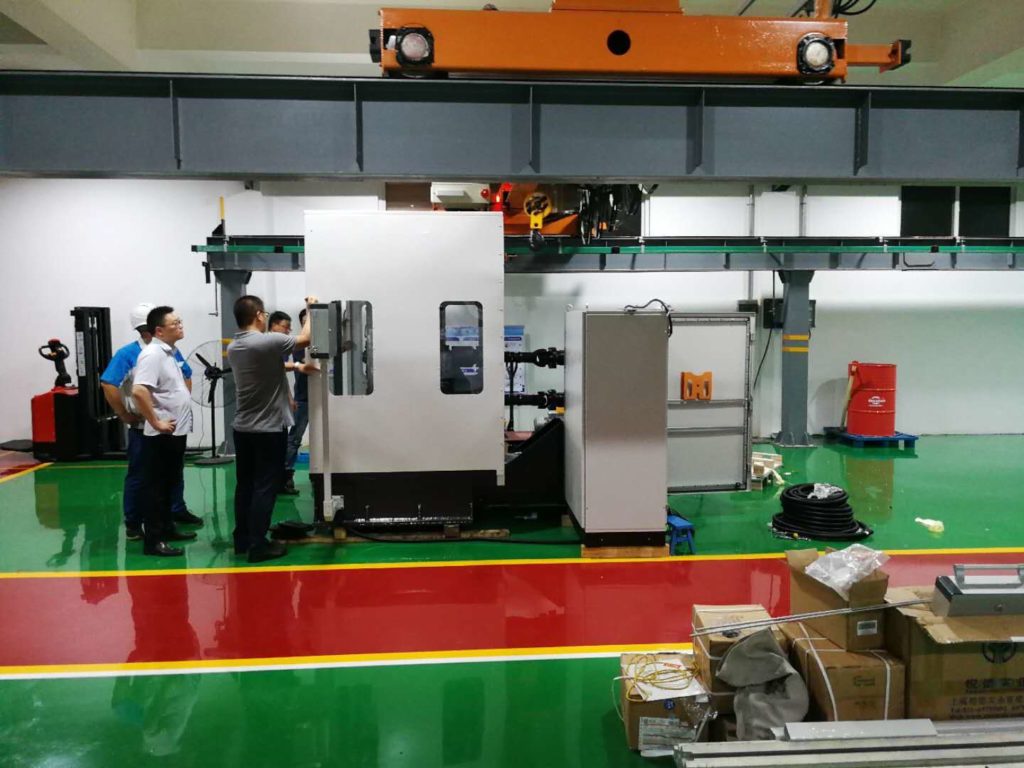

Enhancing Technology Co., Ltd. is a leading manufacturer of precision wire rolling mill. The business scope covers two major business sectors: industrial intelligent core equipment and industrial logistics system integration. The main products include precision wire rolling mill, coiler, induction heat treatment equipment and intelligent factory solutions. Products are widely used in auto parts, electric power, hardware products, consumer electronics, metal wire processing and other major fields

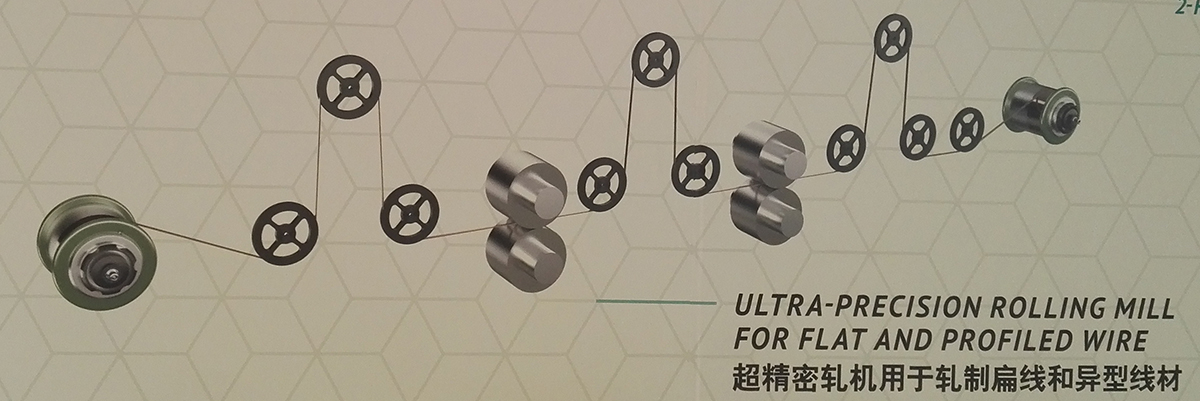

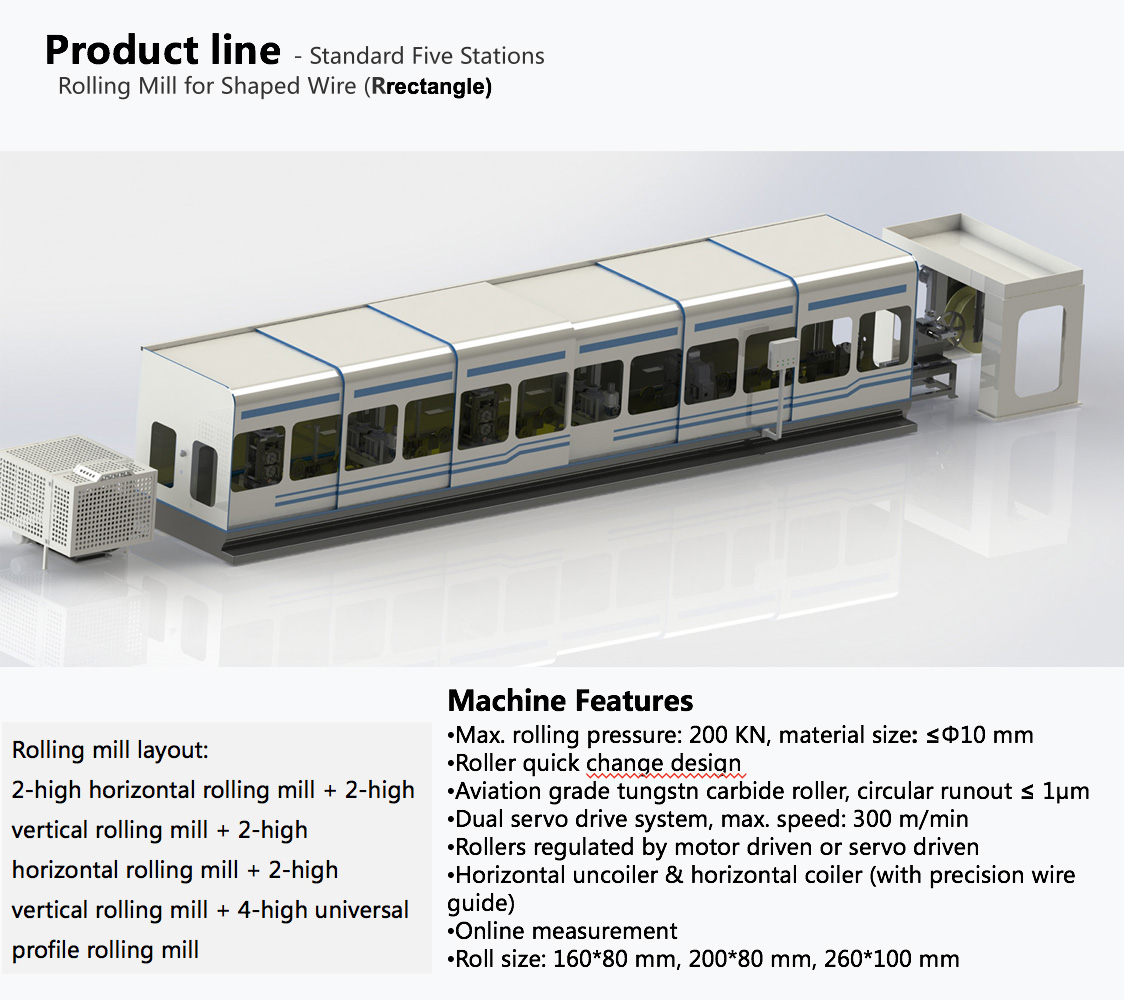

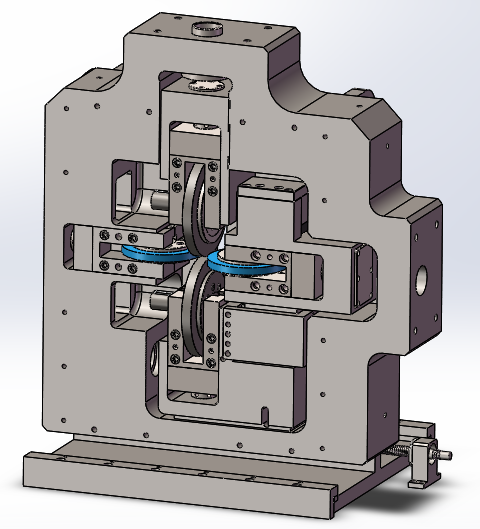

A precision wire rolling mill is usually composed of stringer, straightener, horizontal two-high, vertical two-high, universal four-high, tension device, degreasing and cleaning device, traction device, take-up machine, lubrication system, cooling system, control system and on-line measurement system. It is suitable for rolling rectangular wire or flat wire with high precision. Its advantages are as follows:

- Maximum force 200KN, maximum line 10mm

- Rapid roll change, one-button roll-to-roll

- Minimum roll runout < 0.001 mm for aviation grade cemented carbide rolls

- Double servo drive rolling with maximum linear speed of 300m/min

- Electric/Servo Hydraulic Roll Gap Adjustment

- Active wiring and gantry precision wiring

- Online measurement

- Roll diameter 160*80mm 200*80mm 260*100mm

Wire rolling mill data sheet:

Wire rolling mill data sheet:

Name | Parameter | |

Raw material diameter | Φ0.1~Φ20mm | |

Raw material | Cooper, Stainless steel, Carbon steel, Steel alloy etc. | |

Rolled wire size | Max. width-thickness ratio: 30 | |

Final precision | ≤0.005mm | |

Working speed | 10~600m/min | |

Composition | Payoffs | Per raw material wire. |

Tension | Pneumatic adjustable, servo torque control. | |

Roller | Per rolling method. | |

Inline detection | Real-time Width and Thickness Detection. | |

Cooling system | Cooling medium constant temperature control, precision filtration. | |

Lubrication system | Centralized lubrication and constant temperature control. | |

Straightener | Vertical straightening and Horizontal Straightening. | |

Oil removal system | Air knife oil removal/scraping oil removal. | |

Precision take-up | Precision take-up, layout accuracy 0.2m, I-wheel can be customized. | |

We purchased a Five Stands Flat Wire continuous rolling mill from Enhancing Technology in 2016. Initially, we used it for the preliminary rolling process of our piston ring material. However, when we found that the precision of this rolling mill was +/- 0.003 mm. We immediately changed and put it into the precision rolling process. We have purchased another 5 stands tandem continuous flat wire rolling mill from them this year.

---Tokai Kogyo from Japan

The precision of flat wire continuous rolling mill from Enhancing Technology is amazing. We purchased it for our piston ring production in China in 2017. And we are purchasing more lines from them now. This is a good partner and we enjoy our good cooperation.

---Edmund Kozlowski from Germany